Slack adjusters play a crucial role in the braking systems of vehicles, ensuring safe and efficient braking. These small but important components are responsible for maintaining the proper tension in the brake system, allowing for effective stopping power. Without properly adjusted slack adjusters, the braking system can become compromised, leading to potential accidents and injuries.

In this article, we will explore the importance of slack adjusters in braking systems, how they work, the consequences of improper adjustment, signs of improper adjustment, the dangers of neglecting maintenance, steps for proper adjustment, tools needed for adjustment, common problems and how to fix them, inspection and adjustment frequency, their role in safe and efficient braking, training and certification requirements, and the importance of proper maintenance and adjustment.

Key Takeaways

- Slack adjusters are a crucial component of air brake systems in commercial vehicles.

- Proper adjustment of slack adjusters is essential for safe and efficient braking.

- Signs of improper slack adjuster adjustment include longer stopping distances and uneven brake wear.

- Neglecting slack adjuster maintenance can lead to brake failure and accidents.

- Steps for proper slack adjuster adjustment include measuring pushrod stroke and adjusting the slack adjuster accordingly.

Understanding Slack Adjusters and How They Work

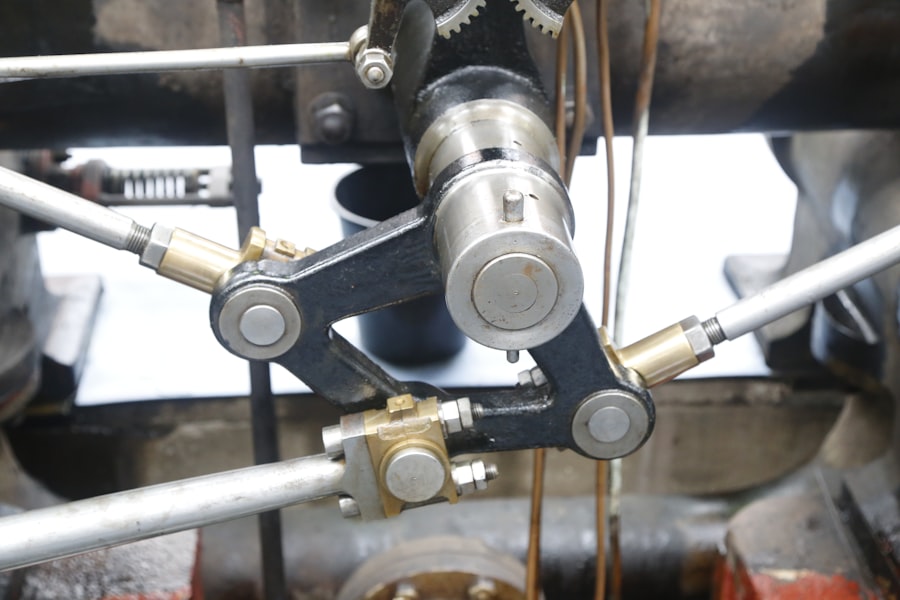

Slack adjusters are mechanical devices that are part of the braking system in vehicles. They are responsible for adjusting the tension in the brake system to ensure proper braking performance. When the brake pedal is pressed, it activates the brake chamber, which applies force to the slack adjuster. The slack adjuster then transfers this force to the brake shoes or pads, causing them to press against the brake drum or rotor and create friction, which slows down or stops the vehicle.

The main function of a slack adjuster is to compensate for wear in the brake linings. As brake linings wear down over time, the distance between the brake shoes or pads and the drum or rotor increases. This increased distance is known as slack. The slack adjuster automatically adjusts itself to take up this slack and maintain proper tension in the brake system. This ensures that there is always sufficient contact between the brake linings and the drum or rotor, allowing for effective braking.

The Importance of Proper Slack Adjuster Adjustment

Proper adjustment of slack adjusters is crucial for safe and efficient braking. When slack adjusters are not adjusted correctly, several issues can arise. Firstly, improper adjustment can lead to reduced braking performance.

If the slack adjusters are not adjusted to take up the slack in the brake linings, there will be a delay in the application of the brakes, resulting in longer stopping distances. This can be particularly dangerous in emergency situations where quick and efficient braking is essential.

Secondly, improper adjustment can cause uneven wear on the brake linings. If the slack adjusters are not adjusted evenly on both sides of the vehicle, one side of the brake system may be applying more pressure than the other. This can lead to uneven wear on the brake linings, reducing their lifespan and potentially causing them to fail prematurely. Uneven wear can also result in uneven braking, causing the vehicle to pull to one side when the brakes are applied.

Lastly, improper adjustment can put additional strain on other components of the braking system. When slack adjusters are not adjusted correctly, other components such as brake chambers and brake drums or rotors may be subjected to excessive force or wear. This can lead to premature failure of these components, resulting in costly repairs and potential safety hazards.

Signs of Improper Slack Adjuster Adjustment

| Signs of Improper Slack Adjuster Adjustment | Description |

|---|---|

| Excessive Brake Lining Wear | When the slack adjuster is not adjusted properly, it can cause the brake lining to wear out faster than usual. |

| Reduced Braking Performance | If the slack adjuster is not adjusted properly, it can reduce the braking performance of the vehicle, which can be dangerous. |

| Increased Stopping Distance | When the slack adjuster is not adjusted properly, it can increase the stopping distance of the vehicle, which can be dangerous in emergency situations. |

| Uneven Brake Pad Wear | If the slack adjuster is not adjusted properly, it can cause the brake pads to wear unevenly, which can lead to further problems. |

| Brake Dragging | When the slack adjuster is not adjusted properly, it can cause the brakes to drag, which can cause excessive heat and damage to the brake system. |

There are several signs that indicate slack adjusters need adjustment. It is important to be aware of these signs and address them promptly to ensure safe and efficient braking. Some common signs of improper slack adjuster adjustment include:

1. Reduced braking performance: If you notice that your vehicle is taking longer to stop or is not stopping as effectively as it used to, it may be a sign that the slack adjusters need adjustment. Reduced braking performance can be dangerous and should be addressed immediately.

2. Uneven braking: If your vehicle pulls to one side when you apply the brakes, it may indicate that the slack adjusters are not adjusted evenly on both sides. This can cause uneven braking and should be corrected to ensure safe handling of the vehicle.

3. Excessive brake pedal travel: If you have to press the brake pedal further than usual to engage the brakes, it may be a sign that the slack adjusters are not adjusted properly. This can result in delayed braking response and should be addressed promptly.

4. Noisy brakes: If you hear squealing, grinding, or other unusual noises when you apply the brakes, it may indicate that the slack adjusters are not adjusted correctly. Noisy brakes can be a sign of excessive wear or misalignment and should be inspected and adjusted as necessary.

The Dangers of Neglecting Slack Adjuster Maintenance

Neglecting slack adjuster maintenance can have serious consequences for the safety of the vehicle and its occupants. When slack adjusters are not properly maintained, several risks can arise.

One of the main dangers of neglecting slack adjuster maintenance is reduced braking performance. As mentioned earlier, improper adjustment can lead to longer stopping distances and delayed braking response. This can be particularly dangerous in emergency situations where quick and efficient braking is essential to avoid accidents.

Neglecting slack adjuster maintenance can also lead to uneven wear on the brake linings. If the slack adjusters are not adjusted evenly on both sides of the vehicle, one side of the brake system may be applying more pressure than the other. This can result in uneven wear on the brake linings, reducing their lifespan and potentially causing them to fail prematurely.

Furthermore, neglecting slack adjuster maintenance can put additional strain on other components of the braking system. When slack adjusters are not properly maintained, other components such as brake chambers and brake drums or rotors may be subjected to excessive force or wear. This can lead to premature failure of these components, resulting in costly repairs and potential safety hazards.

Steps for Proper Slack Adjuster Adjustment

Proper adjustment of slack adjusters is essential for safe and efficient braking. Here are the steps involved in adjusting slack adjusters:

1. Park the vehicle on a level surface and engage the parking brake to ensure that it is secure.

2. Locate the slack adjuster on each wheel. It is usually located near the brake chamber and is connected to the pushrod.

3. Determine the type of slack adjuster you have. There are two main types: manual slack adjusters and automatic slack adjusters. Manual slack adjusters require manual adjustment using a wrench, while automatic slack adjusters adjust themselves automatically.

4. If you have manual slack adjusters, use a wrench to turn the adjusting nut in the appropriate direction to take up the slack in the brake linings. Refer to the vehicle’s manual or consult a professional for the correct adjustment procedure.

5. If you have automatic slack adjusters, inspect them for any signs of damage or wear. Automatic slack adjusters should adjust themselves automatically as needed. If you notice any issues with the automatic slack adjusters, consult a professional for inspection and repair.

6. After adjusting the slack adjusters, test the brakes to ensure that they are functioning properly. Take the vehicle for a short drive and apply the brakes gently to check for any abnormalities or issues.

Tools Needed for Slack Adjuster Adjustment

Proper adjustment of slack adjusters requires specific tools. Here are some of the tools that may be needed for slack adjuster adjustment:

1. Wrench: A wrench is used to manually adjust manual slack adjusters. The size of the wrench will depend on the specific type of slack adjuster being adjusted.

2. Brake adjustment tool: A brake adjustment tool is a specialized tool used to measure and adjust the clearance between the brake linings and the drum or rotor. It is used to ensure that the slack adjusters are adjusted correctly.

3. Safety glasses: Safety glasses should be worn during any maintenance or adjustment work to protect the eyes from debris or other hazards.

4. Gloves: Gloves should be worn to protect the hands from dirt, grease, and other potential hazards.

How to Identify and Fix Common Slack Adjuster Problems

Slack adjusters can experience various problems that can affect their performance. Here are some common problems that can occur with slack adjusters and how to identify and fix them:

1. Excessive wear: Excessive wear on the slack adjuster can cause it to become loose or ineffective. Signs of excessive wear include visible damage or play in the slack adjuster. If you notice any signs of excessive wear, the slack adjuster should be replaced.

2. Corrosion: Corrosion can occur on the slack adjuster due to exposure to moisture or other corrosive substances. Signs of corrosion include rust or pitting on the surface of the slack adjuster. If you notice any signs of corrosion, the slack adjuster should be cleaned or replaced.

3. Misalignment: Misalignment can occur if the slack adjuster is not properly installed or if other components of the braking system are misaligned. Signs of misalignment include uneven wear on the brake linings or noisy brakes. If you suspect misalignment, consult a professional for inspection and adjustment.

4. Stuck or frozen adjuster: Slack adjusters can become stuck or frozen due to dirt, debris, or lack of lubrication. Signs of a stuck or frozen adjuster include difficulty in adjusting the slack or a lack of movement in the adjuster. If you encounter a stuck or frozen adjuster, it should be cleaned and lubricated or replaced if necessary.

How Often Should Slack Adjusters be Inspected and Adjusted?

The frequency of slack adjuster inspection and adjustment will depend on several factors, including the type of vehicle, its usage, and the manufacturer’s recommendations. In general, it is recommended to inspect and adjust slack adjusters at regular intervals to ensure safe and efficient braking.

For commercial vehicles, such as trucks and buses, the Federal Motor Carrier Safety Administration (FMCSA) requires slack adjusters to be inspected at least once every three months or every 3,000 miles, whichever comes first. However, it is important to note that this is a minimum requirement, and more frequent inspections and adjustments may be necessary depending on the specific vehicle and its usage.

Factors that can affect the frequency of slack adjuster inspections and adjustments include the type of vehicle, the weight it carries, the terrain it operates in, and the driving conditions. Vehicles that operate in harsh conditions or carry heavy loads may require more frequent inspections and adjustments to ensure safe and efficient braking.

The Role of Slack Adjusters in Safe and Efficient Braking

Slack adjusters play a crucial role in ensuring safe and efficient braking. They are responsible for maintaining the proper tension in the brake system, allowing for effective stopping power. Without properly adjusted slack adjusters, the braking system can become compromised, leading to potential accidents and injuries.

Properly adjusted slack adjusters ensure that there is always sufficient contact between the brake linings and the drum or rotor, allowing for effective braking. They compensate for wear in the brake linings by automatically adjusting themselves to take up the slack. This ensures that the brakes engage quickly and efficiently when the brake pedal is pressed, reducing stopping distances and improving overall braking performance.

Slack adjusters also work in conjunction with other components of the braking system, such as brake chambers and brake drums or rotors. When properly adjusted, they help distribute braking force evenly across all wheels, ensuring balanced braking and preventing uneven wear on the brake linings. This contributes to safe handling of the vehicle and reduces the risk of accidents caused by uneven braking.

Training and Certification for Slack Adjuster Adjustment

Proper training and certification are essential for anyone involved in slack adjuster adjustment. Adjusting slack adjusters requires knowledge of the specific procedures and techniques involved, as well as an understanding of the braking system and its components.

Training for slack adjuster adjustment is typically provided through vocational schools, technical colleges, or specialized training programs. These programs cover topics such as brake system fundamentals, slack adjuster operation and adjustment, inspection and maintenance procedures, and safety protocols.

Certification for slack adjuster adjustment is often offered by industry organizations or professional associations. These certifications validate the knowledge and skills of individuals in slack adjuster adjustment and demonstrate their competence in performing the necessary tasks safely and effectively.

Proper training and certification in slack adjuster adjustment provide several benefits. Firstly, they ensure that individuals have the necessary knowledge and skills to perform the job correctly. This reduces the risk of errors or improper adjustments that can compromise the safety and performance of the braking system.

Secondly, training and certification provide individuals with a recognized credential that can enhance their professional credibility and career prospects. Employers often prefer to hire individuals who have received proper training and certification in slack adjuster adjustment, as it demonstrates their commitment to professionalism and competence.

Slack adjusters are a critical component of braking systems, ensuring safe and efficient braking. Proper adjustment of slack adjusters is essential for maintaining the proper tension in the brake system, allowing for effective stopping power. Neglecting slack adjuster maintenance can lead to reduced braking performance, uneven wear on brake linings, and additional strain on other components of the braking system.

It is important to be aware of the signs of improper slack adjuster adjustment and address them promptly to ensure safe and efficient braking. Regular inspection and adjustment of slack adjusters are necessary to maintain their proper functioning. Training and certification in slack adjuster adjustment are also important to ensure that individuals have the necessary knowledge and skills to perform the job correctly.

In conclusion, proper maintenance and adjustment of slack adjusters are crucial for safe and efficient braking. By understanding the importance of slack adjusters, recognizing the signs of improper adjustment, and following the necessary steps for adjustment, we can ensure that our vehicles are equipped with properly functioning braking systems that contribute to our safety on the road.

If you’re looking for information on slack adjuster adjustment, you may also be interested in learning about how to fix a gaming chair that is leaning forward. A properly adjusted gaming chair is essential for comfort and proper posture during long gaming sessions. This article provides step-by-step instructions on how to fix a leaning gaming chair and ensure that it is stable and secure. Check out the article here for more details.

Leave a Reply

You must be logged in to post a comment.